Being quality oriented, Yantai Jereh Power-Tech Co., Ltd. pays great attention on the quality of the casting. All incoming casting is subject to strict control by visual and endoscope inspection for casting defects and debris. Chemical analysis and mechanical property inspection are carried out for each lot of casting.

Each head will go through inspections before it is regarded as qualified. Critical dimensions will be inspected by gauge and laser projector. All Bolt holes and water holes will be inspected with a genuine quality gasket. 100% Fuel line inspection and 100% pressure test for each head to detect potential defect in fuel lines and water gallery, 100% vacuum test for each head to achieve proper valve sealing.

Incoming Quality Control

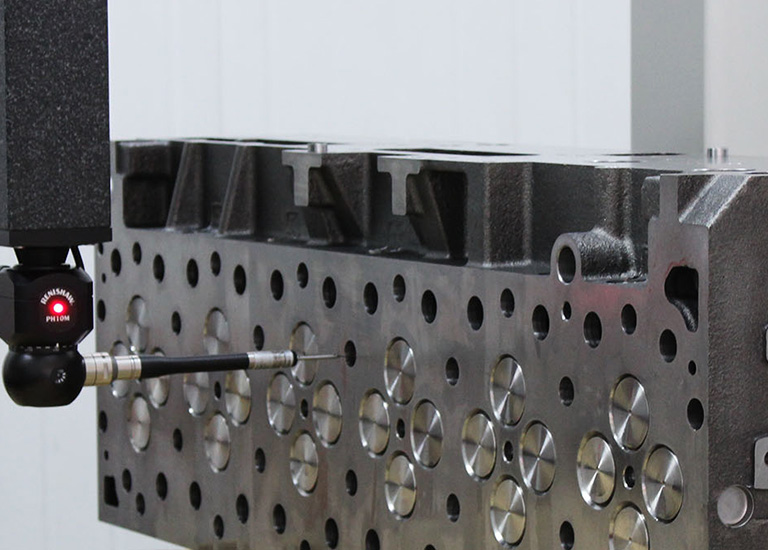

In-process Quality Control

Final Quality Control

Outgoing Quality Control

After Service

-

1

Casting inspection by advanced Endoscopy

-

2

More strict dimension control on critical area

-

3

100% Hot Water Pressure Test

-

4

100% Vacuum Test

-

5

Tensile Test

-

6

Ultrasonic Cleaning